Summary

Nanocomposites are engineered materials that incorporate nanosized particles into a matrix of a conventional material. These nanosized particles, called nanomaterials, when added into a matrix, are referred to as nano additives or nanofillers. Adding nanofillers can drastically alter the properties of a material, including its mechanical strength, toughness, thermal or electrical conductivity, and electromagnetic behaviour.

How small is 'nano'?

When it comes to size, the term ‘nano’ or ‘nanometre’ indicates one billionth of a metre. For reference:

- an Airbus A380 is 73 metres (m) long;

- the average human height is 1.7 m,

- an ant is typically 4 millimetres (mm) long,

- a large raindrop can be 2.5 mm wide,

- a human hair is approximately 100 micrometres (μm, or microns) in diameter,

- the diameter of a carbon fibre is up to 10 μm,

- the SARS-CoV-2 (COVID-19) virus is roughly 140 nanometres (nm) in diameter,

- a single-walled carbon nanotube (SWCNT) is approximately 1 nm in diameter, and

- a water molecule is about 0.1 nm in size.

What is a Nanomaterial?

Nanomaterials are chemical substances or materials in which the majority of constituents particles have at least one external dimension in nanoscale, i.e. 1 to 100 nm (or 10–9 to 10–7 m). Nanomaterials are synthesised to exhibit unique characteristics compared to the same material without nanoscale features, such as increased mechanical strength, chemical resistance, thermal and electrical conductivity. Nanoparticles making up the nanomaterial can be in spherical, tubular or platelet form, or a combination thereof.

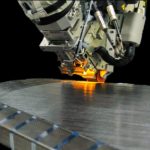

How do they look under a high-resolution electron microscope?

Spherical Nanoparticles

Material having all three external dimension in the nanoscale, e.g. nano-SiO2.

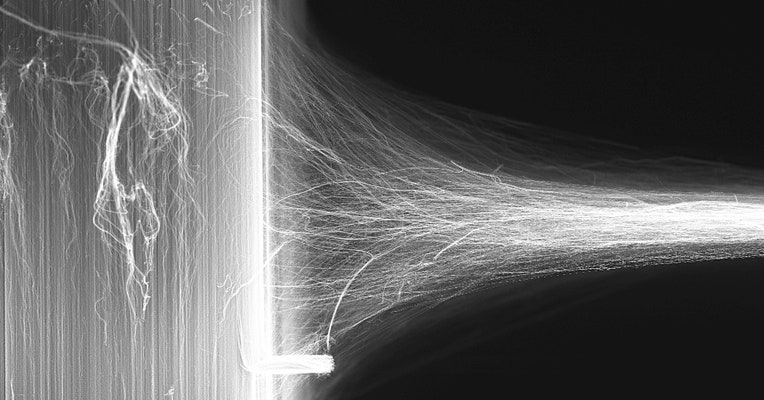

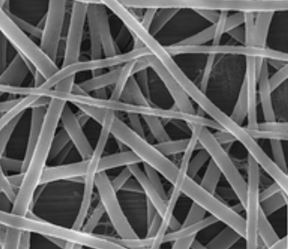

Nanotubes

Material having two external dimension in the nanoscale, e.g. carbon nanotubes.

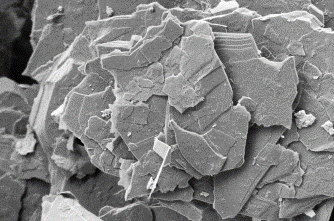

Nanoplatelets

Material having only one external dimension in the nanoscale, e.g. graphene.

What are Nanocomposites?

Nanocomposites are a multiphase composite material in which the matrix (which could be a thermosetting polymer, thermoplastic polymer, ceramic or metallic) is combined with one or more types of nanomaterials. There may be some form of conventional reinforcement, such as fibres or particulates, included in the system. Similar to regular composites, nanocomposites can also be classified into three categories based on the matrix material type:

- Polymer-matrix Nanocomposites

- Ceramic-matrix Nanocomposites

- Metal-matrix Nanocomposites

Benefits and inner workings of Polymer Nanocomposites

When nanomaterials are added to a polymer matrix the resulting nanocomposite may demonstrate the following characteristics, or a combination thereof:

- improved mechanical strength and fracture toughness

- improved thermal and electrical conductivity

- improved fire performance

- improved barrier property

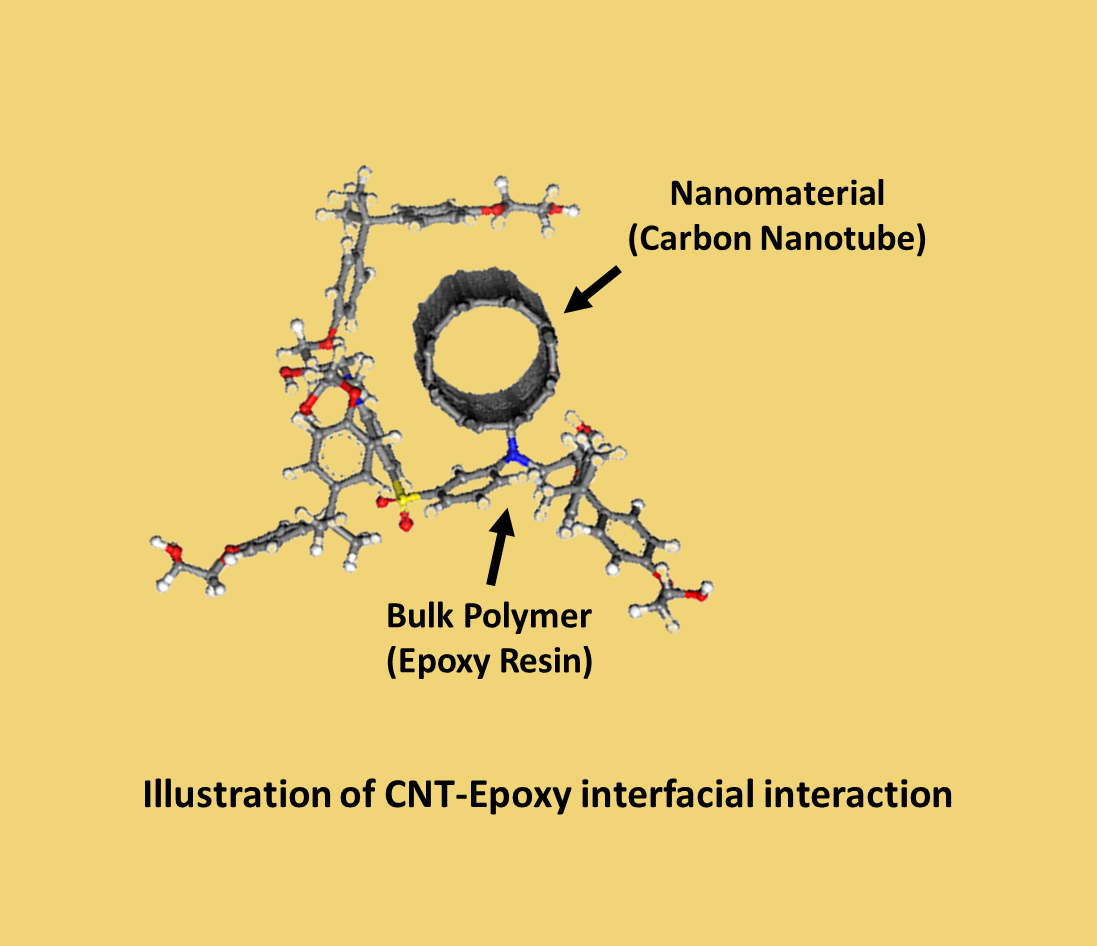

In nanocomposites, increases in the mechanical performance are generally attributed to the large surface area interface between the two constituent materials, namely, the nanofiller and the bulk polymer. Good compatibility between the two constituents is a prerequisite as it allows for an efficient stress transfer between the two.

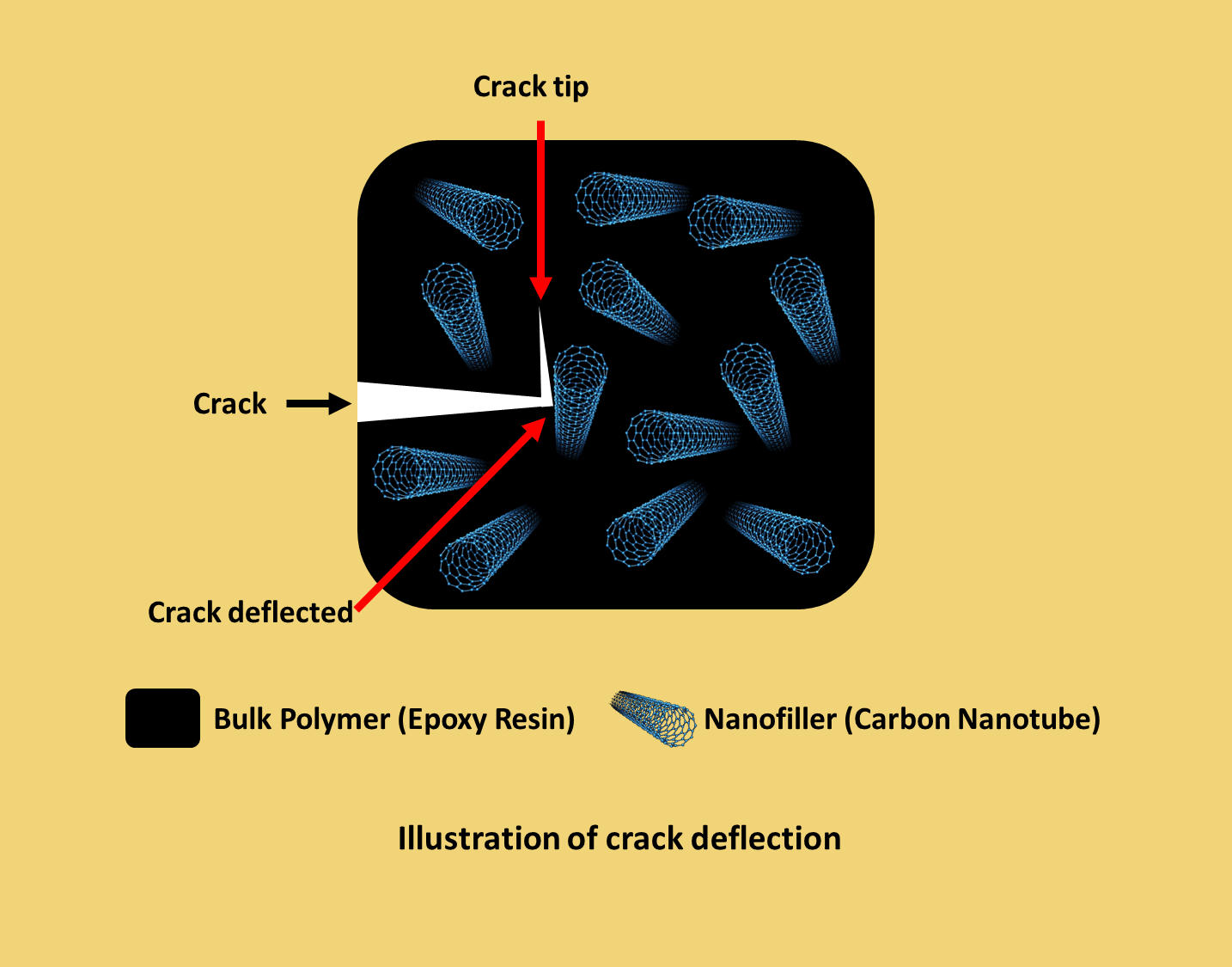

Fracture toughness is a property which describes the ability of a material containing a flaw, such as a crack or a void, to resist further fracture. Certain nanofillers are speculated to improve the fracture toughness by either deflecting or bridging cracks within the composite.

Crack Deflection

Nanomaterials having tubular or platelet like structure can be effective at deflecting cracks, resulting in a total crack area that is larger than previous. More energy is absorbed before the crack can propagate further, thus increasing the fracture toughness.

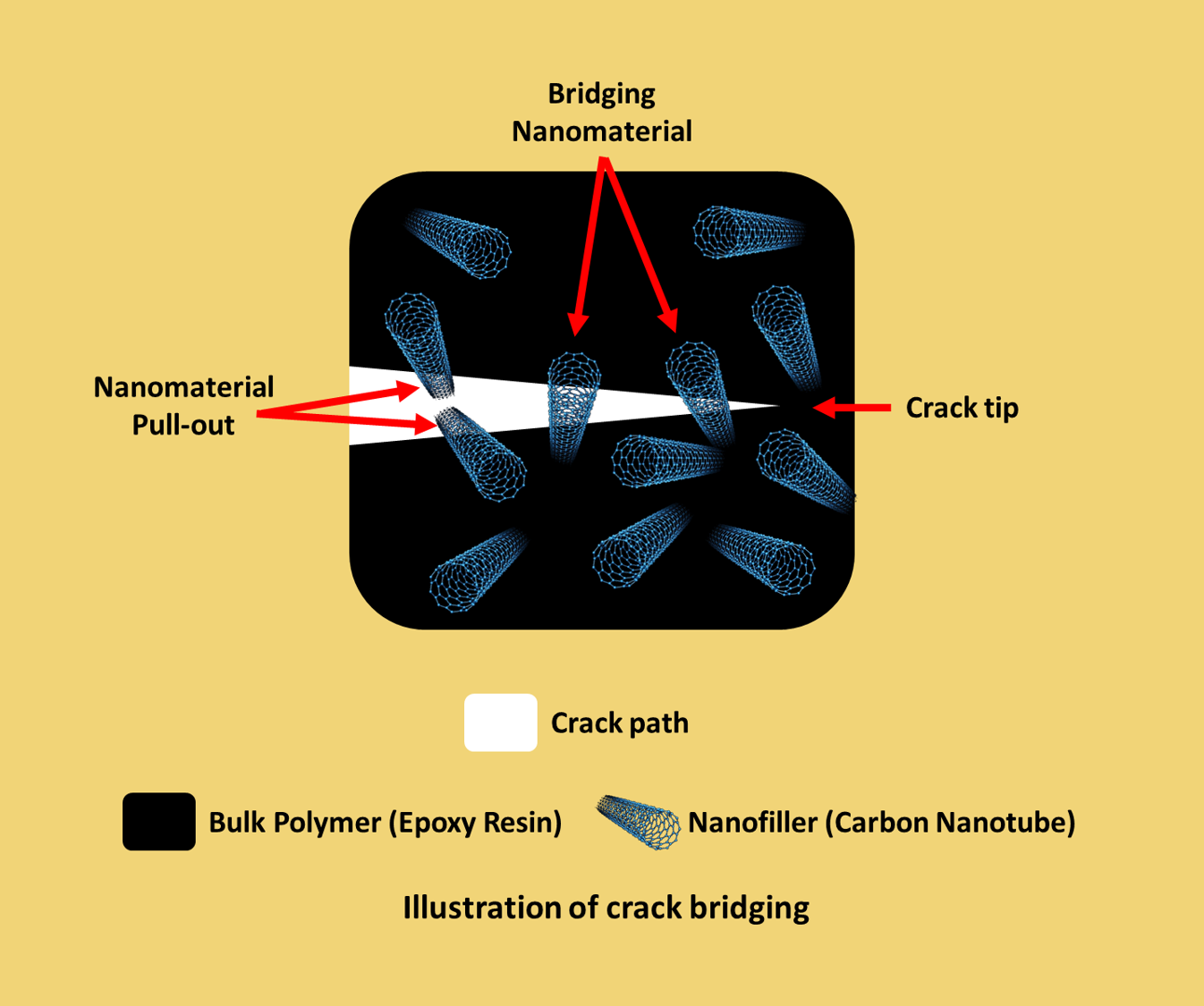

Crack Bridging

Nanomaterials with high aspect ratio can be effective at bridging cracks as they propagate through the matrix. More energy is required to counter the frictional pull-out or breakage of the bridged nanomaterial, thus reducing the rate of crack propagation and increasing the fracture toughness.

Insulating polymers can be are transformed into thermally or electrically conductive composites by adding suitably conductive nanomaterials above a critical concentration threshold (known as percolation threshold). When the positions of nanofiller in the polymer matrix form a conducting network, the conductivity of composite sharply increases. This phenomenon is known as percolation. Electrical percolation thresholds for some CNT/polymer composites were reported as ranging from 0.0021 to 15 wt%. In some cases it was found that agglomerations, i.e. dense clumping of nanomaterial in a matrix, can be favourable in increasing the electrical conductivity.

Uniformly distributing nanomaterials in a bulk polymer that was inherently gas permeable can show improvements in gas barrier properties. The reasoning behind this is that the homogenously dispersed nanomaterials form a tortuous path, which any gas or vapour molecule must traverse in order the permeate through the bulk polymer.

Nanomaterials are shown to improve the fire performance of composites. It is hypothesised that a burning of some nanofillers contribute to the formation of a more robust char layer. This char layer provides a physical barrier which cuts-off/limits the supply of much needed oxygen to the unburnt polymer underneath, and on the other hand this char layer prevents flammable volatiles from being released from the bulk material.

Why Datum is working with Nanocomposites?

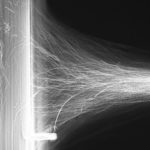

You may have heard about Graphene, a wonder material, carbon-based nanomaterial with exceptionally high mechanical strength, stiffness, electrical and thermal conductivity. The challenge is to transfer its superior properties from nanoscale to a macroscopic level. If done correctly, we can manufacture lightweight multifunctional composite structures from such novel materials ideal for high-performance applications, such as aeronautics, defence and space exploration. The potential to combine different nanomaterials with conventional FRP composites and develop far superior nanocomposites without the limitations of the latter makes it an exciting field to work in.

At Datum we extensively work with Polymer Nanocomposites. We develop processes to combine novel nanomaterials, such as graphene, carbon nanotubes gold and silver nanoparticles, with polymer matrix by means of dispersion, interleaving or coating the fibre reinforcement with one. We prepare nanocomposite specimens and characterise their material properties for our customers, such mechanical strength, interlaminar properties, electrical and thermal conductivity. We have the capability to evaluate the performance of your nanomaterial when integrated in a conventional FRP composite. Please contact us to discus further.