Composite Moulding Processes We Employ

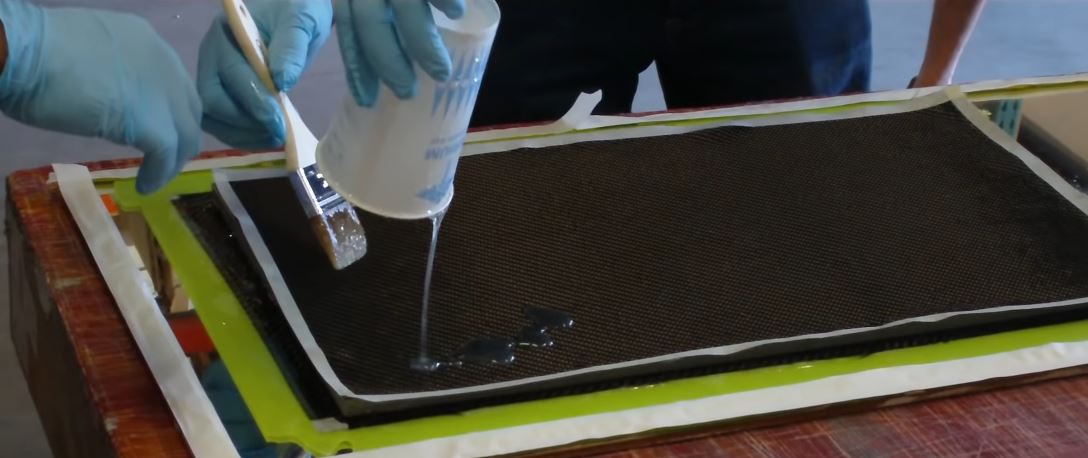

Wet / Hand Layup

Wet / Hand Layup is a low-cost manual composite moulding process requiring relatively inexpensive low-temperature tooling. It involves impregnating the fibre reinforcement by hand, either off-the-mould or in-the-mould. Brushes and rollers are used for wetting out and consolidating the laminate. The finished product is usually cured at room temperature before de-moulding. This method is employed, where ultimate laminate quality and performance are not the crucial drivers. Structures requiring a core are usually manufactured in multiple stages. Datum uses all compatible fabrics, gelcoats and resin systems.

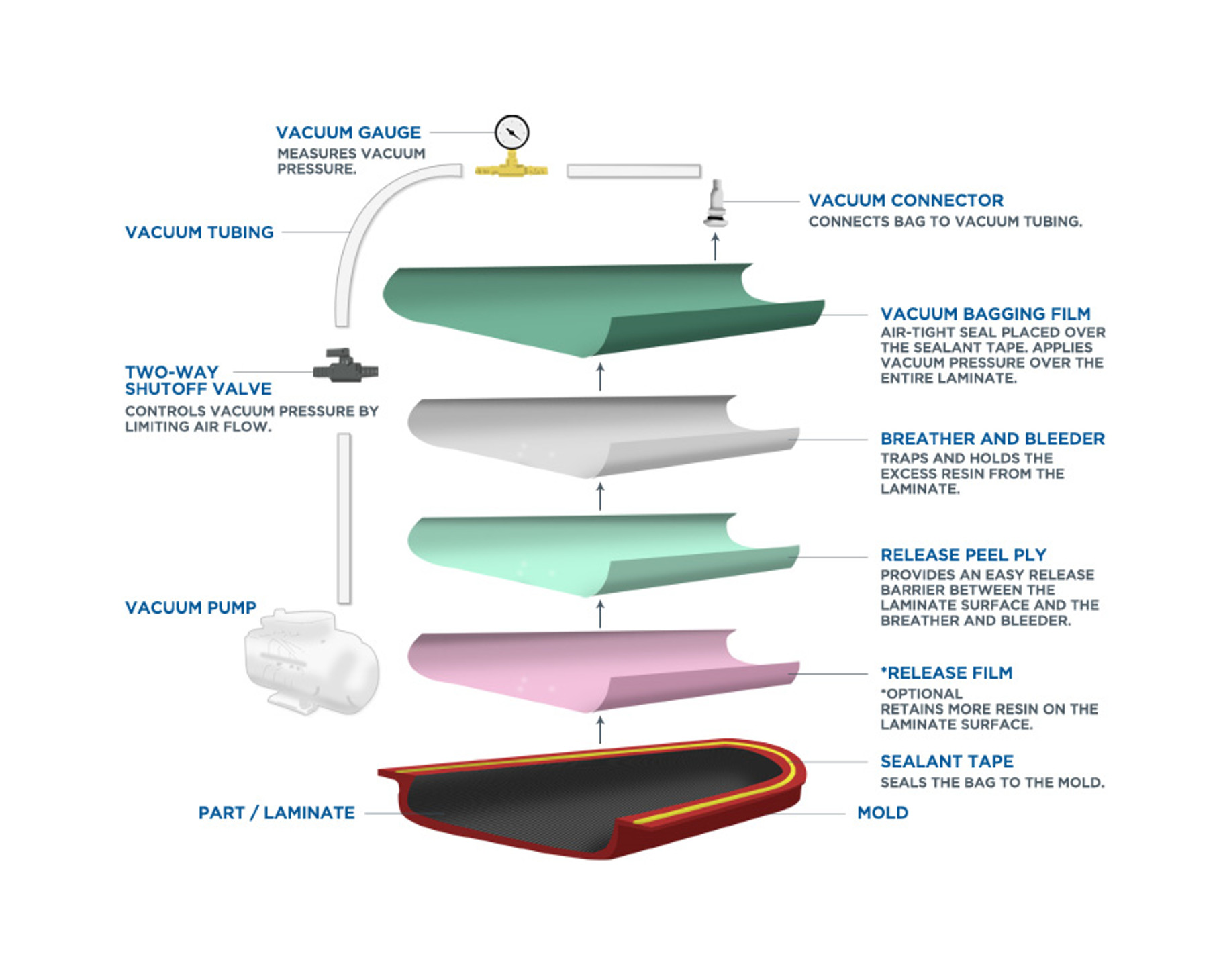

Vacuum Bagging

Vacuum Bagging is a process where pressure is applied on a layup to improve its consolidation and wetting of reinforcement fabrics. Employing this process also increases the fibre content of laminated composite and decreases the void content, thus providing a lighter component with improved mechanical performance. This process is used as an extension of the wet layup process by sealing a polymeric vacuum bagging film over the wet laid-up laminate and onto the tool. The air under the bag is extracted using a vacuum pump and thus pressure of up to 1 atmosphere (approx. 1 bar or 14.7 psi) can be applied to consolidate the laminate.

Resin Infusion

Resin Infusion is a composite moulding process in which liquid resin is drawn into a layup of dry reinforcement fabric with the help of vacuum pressure. In this process dry fabric layup is covered with a porous nylon peel ply, and a polymeric infusion mesh for even resin distribution, the stack is vacuum bagged and once any identified air leaks are eliminated, resin is allowed to flow into the laminate. During infusion, liquid resin impregnates the laminate using vacuum pressure as the driver. Datum ensures even resin distribution over the whole laminate through careful design of the vacuum and resin injection system. Resin infusion process offers similar advantages to the RTM process and is more feasible to use for one-off components or for limited runs due to a lower cost of tooling. At Datum we use liquid resin infusion to produce a wide variety of composite parts and tooling where it suits the requirement.

Preforming

Preforms are layers of dry textile cut to pre-defined dimension and stacked in specific fibre orientation as per design specification, and held together during dry preforming process. Preforming plays a large role in the configuration and cost-effectiveness of the process. The better the preform, the better the structural part.

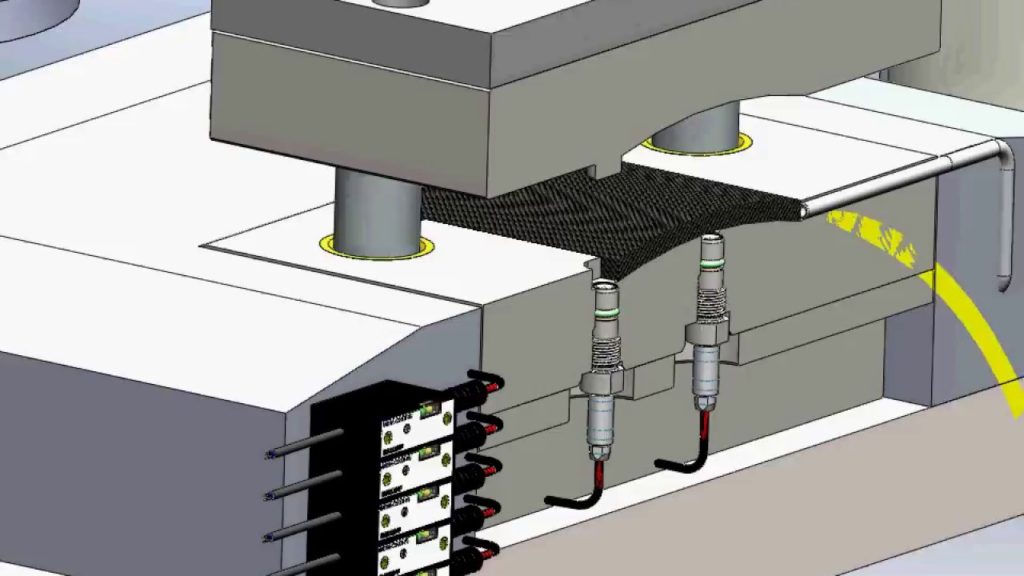

Resin Transfer Moulding

Resin Transfer Moulding (RTM) is a moulding process in which reinforcement fabrics are laid into a mould either individually or as preform. A second mould tool is then clamped over the first, and resin is injected into the cavity. Vacuum can also be applied to the mould cavity to assist resin in being drawn into the fabrics. Both resin injection and curing can take place at either ambient or elevated temperatures. RTM can provide moulded surface finish on both sides of the component. The tooling used in this process is more expensive but the cost can be spread over multiple components, where applicable. Therefore, RTM is not often used for producing one-off components.

Prepregs

Prepregs are reinforcement fabrics and fibres pre-impregnated with a pre-catalysed resin system, under heat and pressure or by using solvent. The catalyst (also known as hardener) is often coupled with an accelerator and is largely latent at ambient temperatures giving the material several weeks, or sometimes months, of useful life when defrosted. For a prolonged shelf-life prepregs are generally stored in freezer at temperatures up to -18ᵒC or lower. Prepregs can be manufactured by impregnating a range of unidirectional or woven fabrics, or fibres from creels of glass, carbon, aramid, other thermoplastic or natural fibres with a variety of epoxy, polyester, phenolic, polyimide, cyanate ester or bismaleimide resin systems. The resin system in prepregs is usually in a near-solid state at ambient temperatures, thus prepregs have a light sticky feel to them, often referred to as the ‘tack’, such as that of an adhesive tape.

Prepreg Moulding

Prepreg moulding, is a process in which multiple layers of prepreg material are placed on a mould surface by hand or machine, vacuum bagged and then heated to typically 120-180ᵒC, as prescribed by the material manufacturer. Initially, the resin changes from near-solid to liquid state and reflows within the layup, then finally cures to form a solid composite laminate. Vacuum bagged prepreg layups can be cured in composite curing ovens. Autoclaves are often used to exert additional pressure of up to 5 atmospheres (approx. 5 bars or 73.5 psi) during the curing process, depending upon the manufacturing requirements. Datum is proficient in using prepregs to produce composite components that demand superior mechanical properties.

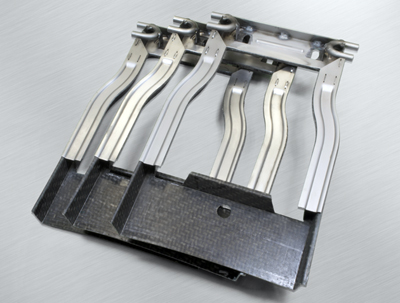

Compression Moulding

Compression Moulding is a precise and potentially speedy process for manufacturing high quality composite components, and well suited for high-volume manufacturing. A matched metallic tooling (having male and female sections) is heated in a press (often hydraulic) to consolidate sheet materials or moulding compounds at relatively high pressures. Datum uses all materials that are commonly processed by compression moulding which include prepregs, fibre-reinforced thermoplastics sheets, sheet moulding compounds (SMCs) and chopped thermoplastic tapes. Besides monolithic composite parts, sandwich structures containing core material such as honeycomb or polymeric foam can also be processed using compression moulding, although considerations should be made not to use excessive pressure that may crush the core.

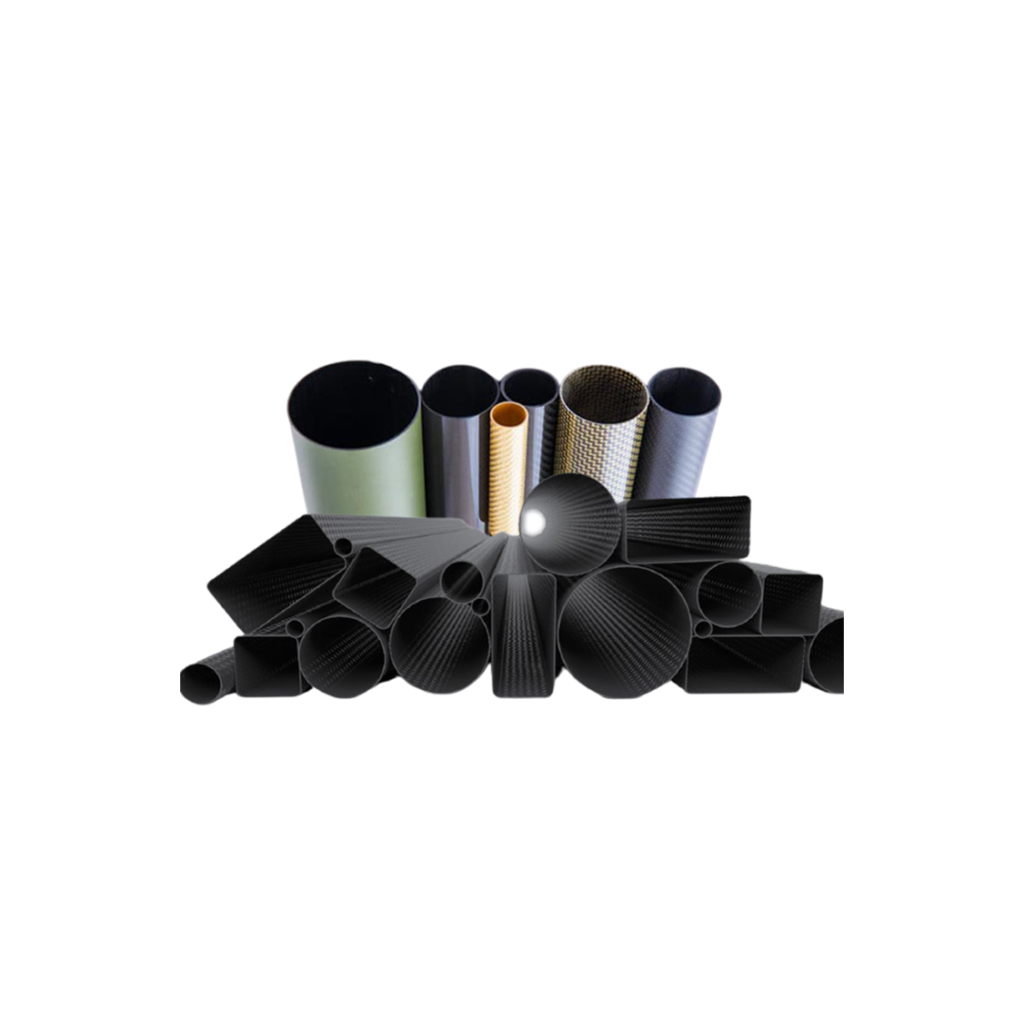

Roll Wrapping

Roll wrapping process is used to produce high strength fibre reinforced polymer (FRP) composite tubes, either with a basic unfinished appearance or having a cosmetic finish. The process involves wrapping prepreg fabric around a metal mandrel having the correct diameter for the size of tube you wish to get fabricated, the outer diameter (OD) of the mandrel should match the inner diameter (ID) of the tube. A Mandrel having either parallel sides or a continuous taper is required to manufacture roll wrapped composite tubes. The thickness of the tube will dictate the amount of reinforcement fabric that will be required to fabricate a conforming product. Prepreg reinforcement is wrapped around the mandrel tightly and consolidated using composite shrink tape. The prepreg wrapped mandrel is then placed in a composite curing oven for curing. The cure cycle is prescribed by the material manufacturer. Datum offers a wide range of roll wrapped tubes made to specific dimensions, fibre type/orientation or appearance requirement.

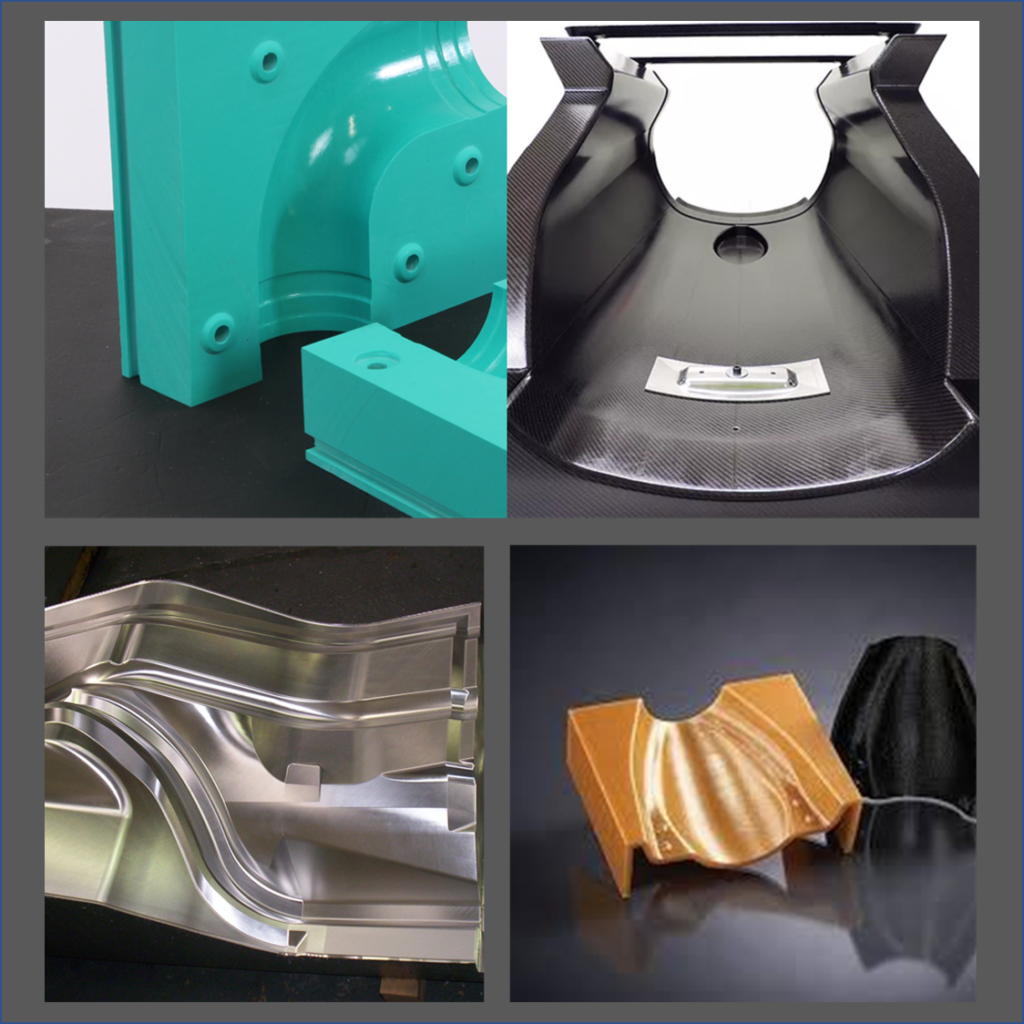

Tooling for Composites

Tooling that is well-designed and meticulously fabricated is fundamental to achieving a good quality component capable of meeting or exceeding its performance criteria. Datum manufactures and supplies high-quality, fit for purpose moulds, plugs, fixtures, jigs and other tools from a range of appropriately selected materials, most commonly timber, polystyrene, tooling block, tooling paste, GRP, advanced composites or metals. All male and female moulds are manufactured to meet the specified surface finish of the part. Jigs and fixtures are produced to assist the maintenance of dimensional tolerances when machining moulded parts or assembling separate components into one unit.

Machining of Composite Components

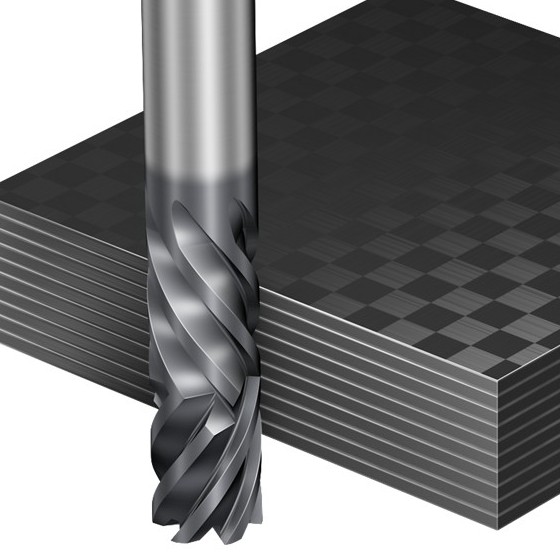

Computer Numerical Controlled (CNC) Machining

Machining FRP composites is more difficult than machining metals mainly because composites components are anisotropic, non-homogeneous and their reinforcing fibres are very abrasive. During composite machining, defects are introduced into the workpiece, and tools wear rapidly. Additional process control, precision and expertise is required to mitigate above scenarios and efficiently machine a composite workpiece. At Datum, we take pride in machining highly-complex composite geometries using state-of-the-art 3-axis CNC machines. Our skilled CNC Programmers, Machinists and Engineers first evaluate customers’ engineering data, and then design and develop personalised CNC program for each project, powered by industry-leading software solutions.

Surface Finishing

Based on our customers' exact requirement or from the flow-down of design directives, we proactively incorporate surface finish elements in our design for manufacture strategy. Whether it is the use of gelcoats, surfacing veils or laminating resins, we meticulously control and adhere to our processes and achieve required surface finish and exterior features.

Composite Inspection and Non-Destructive Testing

Visual Inspection / Visual Testing

Decades of experience is required to effectively perform visual inspection on composite structures. Datum's expert Quality Inspectors and Quality Control Engineers are well-versed in visually assessing the damages on composite components. We are capable of checking for all categories of damages listed in Airbus, EASA, Boeing or FAA damage definitions, or specifically asked by our valued customers. Some of the common defects that are visually inspected in composites are surface cracks, disbond, chipped, missing, loose or blistered paint, etc.

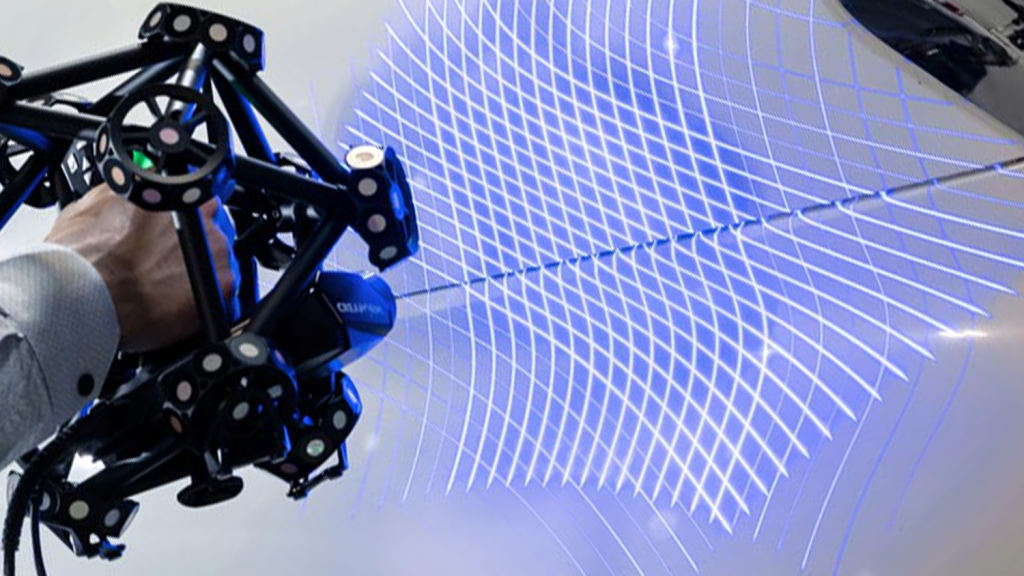

Dimensional Conformity Measurement

Datum uses conventional dimension measurement devices like callipers and gauges and bespoke fit-check tools, giving our customers the confidence that they are receiving a dimensionally conforming product. Our meticulously-trained quality inspectors and engineers can perform both on-site and off-site dimensional checks using state-of-the-art measuring tools. We are confident that the structural parts we supply meet the precise tolerances specified by the Design Office.

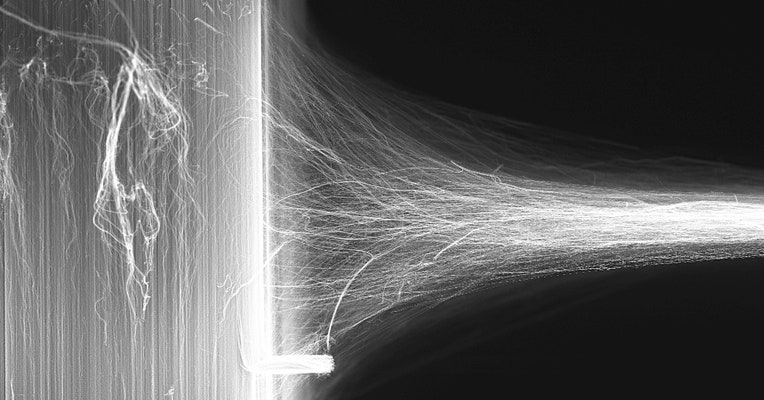

Non-Destructive Testing and Evaluation

Team Datum and their supply chain has extensive experience in testing composite structures using a wide range of Non Destructive Test (NDT) equipment and techniques, including ultrasonics, penetrants, magnetics, radiography, eddy currents and laser shearography. This allows us to inspect a huge range of complex composite materials from super yachts to stealth aircraft, with minimal contact and without damage to the materials.

Bespoke Processes

Composite Joining & Assembly

Composite parts can be joined with mechanical fasteners, adhesives and welding. Thermoset composites are usually joined by adhesive bonding, while thermoplastic composites are typically joined by welding. Fasteners are primarily used to join aerospace composites. Composites are easily joined to dissimilar materials as long as the process is carried out correctly. Manufacturing Engineers and Composite Joiners at Datum have the relevant experience to plan and execute bonding assembly of discrete composite-composite, composite-metal and composite-non-metal structures.

Paints & Coating

There are a variety of paints and coatings that are applied on high-performance composite components, sometimes to prevent from static charging, lightning strike, high-intensity impacts, liquid-interaction, etc. Each coating is unique based on the purpose it serves, so is their application method. Datum's Paints & Coating specialists ensure that the product supplied has been protectively coated as per design instructions.

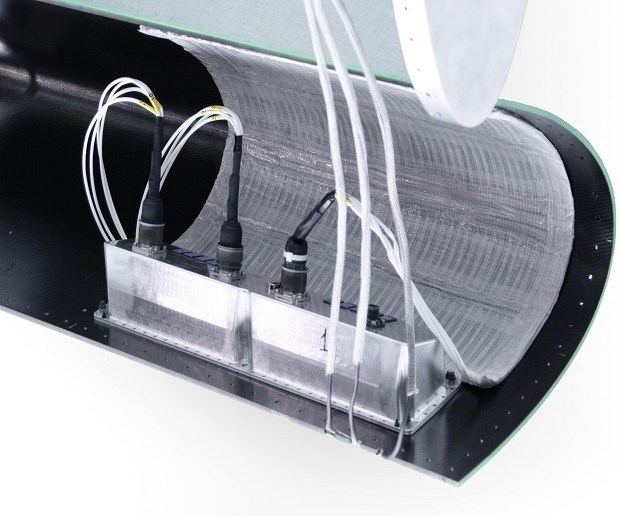

Electronic & Electrical Integration

At Datum Advanced Composites, we have experience installing intricate electrical systems and sophisticated electronics into composite structures. You can count on our Electrical and Electronics experts to provide you with a lightweight, functional part with integrated systems that will perform as expected.

Composite Repairs & Structural Modifications

Unlike metallic structures, repairing, maintaining and modifying composite components is a complicated multi-step process. It all starts with assessing the mechanical and thermal response of the component when subjected to operation loads and environment. The impact of modifications and repairs on operational performance and service life is carefully studied. Product may need to be re-qualified before inducting them back into service. Hence, components may require a full product quality assessment. At times, the part cannot be removed from the system for an in-house job. Our operators and an engineer are agile to turn up on-site to conduct periodic maintenance, structural repairs, overhaul or modifications, if necessary.

Nanocomposite Processing

Graphene, carbon nanotubes (CNTs) and other types of nanomaterials are increasingly being used as additives in regular FRP composites to make them more desirable for high-performance applications. These nano-additives (or nano-fillers) are added to conventional FRP composites using dispersion, interleaving or direct synthesis on fibrous substrates. When processed together, the new material is often referred to as Nanocomposites. Nanocomposites are designed to provide multifunctional capabilities inherently lacking in traditional FRP composites, such as lightning strike protection, through-thickness reinforcement, in-situ structural health monitoring, electromagnetic interference shielding, etc., or a combination thereof. Our scientists, engineers and industry experts have the relevant know-how and experience to develop and manufacture nanocomposite components that address your operational requirements.