Material Qualification

Datum Advanced Composites' Material Qualification service includes everything from processing composite laminates and structures using customer-prescribed material and processing parameters to machining and preparation of specimens, conditioning of specimens, testing of coupons, and detailed analysis and reporting of the results. Our experienced Materials and Process Engineers and Test Technicians offer comprehensive management and execution of your composite processing and testing requirements.

Product Evaluation

We draw on our team's extensive experience in evaluating components within the aerospace and defence industry. Team Datum has extensive experience in planning, conducting and reporting first article inspections (FAI), and based on the assessment improving the product quality. Datum Advanced Composites offers a reliable product evaluation service that encompasses tearing down discrete composite components and systems for FAI and product quality assessment purposes. We also conduct Failure Analysis of components for test verification purposes. Contact us for further discussion.

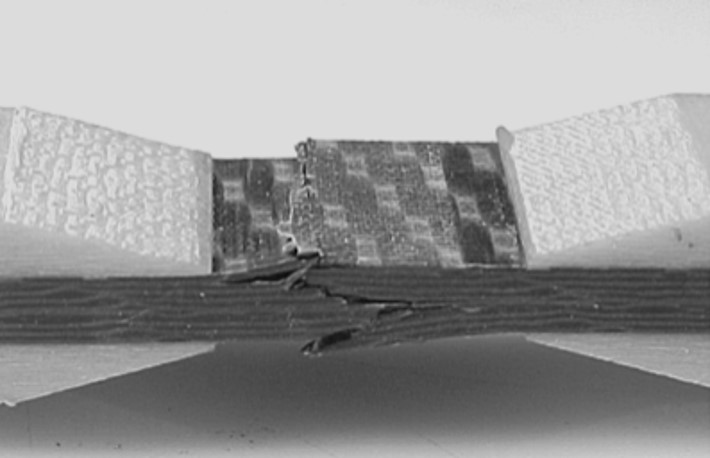

Specimen Preparation and Conditioning

Accurate specimens are a prerequisite to obtaining test results with a high confidence level. Preparing test specimens can be a meticulous task. If you find manufacturing of specimens time-consuming and costly and wish to free your staff to do more value-added tasks, then use the Datum Advanced Composites' Specimen Preparation and Conditioning service. This service includes machining of the laminates, end tabbing, measurement of specimens and conditioning in hot/wet environments or fluid immersion.

Specialist Testing

Due to the specialist nature of some tests, you may be required to arrange work through several different test labs, which can be challenging to manage and control. Datum understands this and, where possible, offers to organise and manage any testing that we do not currently provide through our extensive network of labs that we have built up—allowing you to deal with a single organisation, i.e. Datum, to accomplish all your testing requirements.

Material Testing We Currently Offer

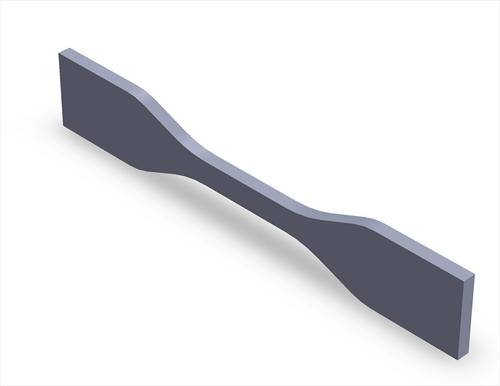

Mechanical Testing

Tensile | Compression | In-plane Shear | Rail Shear | Interlaminar Shear | 3-point and 4-point Flexural | Open-Hole Tension and Compression | Peel Test | Single and Double Overlap Shear | Flatwise Tensile | Tube Testing | Heat Deflection | Short-Term Creep | Bearing Strength |Climbing Drum Peel

Analytical Testing

Density of Core Materials | Void Content | Moisture Content Analysis | Moisture Absorption | Fibre Volume Fraction | Cure Behaviour | Gel Time

Thermal Testing

Differential Scanning Calorimetry (DSC) | Dynamic Mechanical Analysis (DMA)

Electrical Testing

Volume and Surface Resistivity

Surface Analysis

Surface Free Energy | Surface Tension | Barcol Hardness | Microscopy | Cured Ply Thickness | Voids and Defect Size and Frequency Measurements